About Drills

The Important Information

Correct selection of drills is very important when using

implant surgical guides. But what should you use?

1. Freehand Drills

Computer guided implant surgery represents a giant leap forward in the placement of implants and ultimately the restored teeth. However, when using guides drill selection is a very important part of the whole process and if not done correctly will result in compromised results or failure.

2. Tapered and Profiling Drills

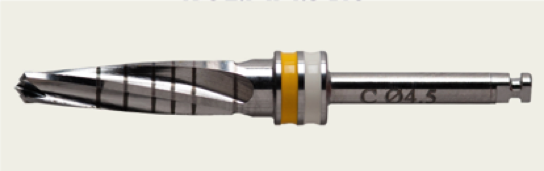

Tapered and shaping/profile drills do not work with surgical guides as they will not be guided correctly in the drill tube due to the tapered shape of the drill. Tapered drills that are suitable for use with guides are always part of a specific guided surgical kit and have a special skirt built in to guide them into the tube. Shaping/profiling drills not designed for guided surgery can be used in the osteotomy procedure but always remove the guide before using them.

3. Parallel Drills

Parallel drills without stops will fit in the parallel walled drill tubes in the surgical guide but it is important to make sure you have adequate length drills. Normally they come in two sizes,usually a short and a long. This will give you maximum flexibility when using drills in different areas of the mouth.

4. Drill Spoons

5. Drill Length Value (DLV)

Freehand drills are great for freehand surgery but are generally too short for guided surgery and often have “stops” built into them.They will not fit into the metal drill tubes correctly because of the built in stop and will likely stop too short and/or get stuck in the drill tube. They work well for freehand drilling but are not suitable for use when using surgery guides.

Generally “freehand” drills and freehand surgical kits are not suitable nor recommended for guided surgery.

Tapered and Profiling drills are generally not suitable for guided surgery unless they are part of a guided surgery kit.

Unless you are using a specific guided surgical kit you will generally need parallel drills without stops

Drill spoons, or sometimes called drill keys or drill handles, are an excellent way to use different size drills through the same drill tube in the surgical guide. They fit intimately into the drill tube and accommodate different drill sizes exactly. Kits of drill spoons are available from various implant companies.

If you dont have a dedicated guided surgical kit an excellent way to use multiple drill widths accurately when using a surgical guide is to use a set of universal drill spoons

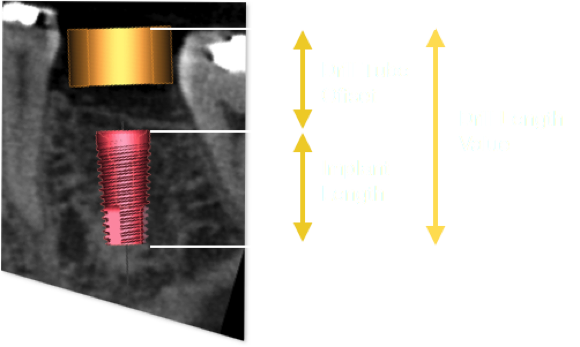

Drill Length Value is the sum of the implant length and the drill tube offset. This offset value is normally measured from the interface of the implant to the top surface of the drill tube. When using drill spoons the drill length value is increased by the thickness of the drill spoon used.

Controlling drill depth when using guides can be a challenge and needs careful consideration.

You will need to know the correct Drill Length Value

We supply this value for every implant in our report

* Of course you are using a dedicated guided surgical kit drill depth is already calculated for the kit.

It is very important to know exactly the Drill Length Value needed when using guided surgery. The good news is this will be supplied to you in a tabulated format in the guided surgery report along with the implant information. Once you know the desired drill length value you can asses the best way to obtain this in your drills prior to the surgery procedure.

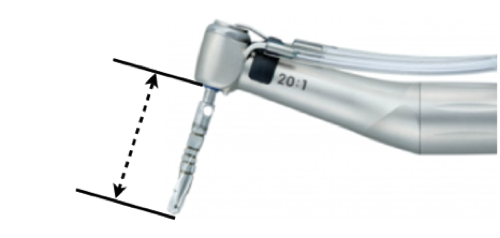

Different handpieces have different chucks and therefore will allow a differrent length of drill to protrude from the chuck depending on handpiece brand.This is why it is very important to measure and know the length of the drill protruding from the handpiece when using parallel drills for guided surgery. We call this the Effective Drill Length.

To measure the Effective Drill Length (EDL) insert your drill into the handpiece and measure the length from chuck to tip of drill. If it is equal to the DLV it can be used without modification. If it is greater use an "O Ring" threaded onto the drill to mark the DLV. You can also use the plastic drill stops that we supply with every case to assist maching to the DLV.

*NOTE: It is common practice to drill 0.7-1.0 mm deeper than the exact supplied calculated DLV to compensate for the drill chisel end geometry and not have the implant "bottom out" when placed.

How to measure your Effective Drill Length (EFD)

General Summary For Guided Surgery

Correct selection of drills is very important when using implant surgical guides

Do not use freehand drills in guides

Do not use tapered drills ( unless part of a guided surgery kit)

Do use parallel drills of correct lengths

Do use drill spoons for multiple drills

Do know drill length value and adjust your drills accordingly

If guided surgical kit not available use guide for pilot drill and finish osteotomy with freehand drills with guide removed

© 2003 - 2021 Fabdent Products and Services

Drill Length Value (DLV)

6. Effective Drill Length (EDL)

Online Form